| Availability: | |

|---|---|

| Quantity: | |

leimeng

Introducing the High Sensitivity Automatic Fabric Clothes Scanner Metal Broken Needle Detector, a cutting-edge product designed to enhance the safety and efficiency of your garment production process. This state-of-the-art device is equipped with advanced technology that can detect even the tiniest metal fragments, ensuring that your garments are free from any potential hazards.

With its high sensitivity capabilities, the detector can quickly and accurately identify any broken needles or other metal debris that may have inadvertently found their way into your fabrics. This not only helps to prevent injuries to your workers but also ensures that your products meet the highest quality standards.

The automatic functionality of this detector allows for seamless integration into your production line, reducing the need for manual inspections and increasing productivity. The device is also incredibly easy to use, with a user-friendly interface that requires minimal training.

Investing in the High Sensitivity Automatic Fabric Clothes Scanner Metal Broken Needle Detector is a smart choice for any garment manufacturer looking to improve safety and quality control. Order yours today and experience the peace of mind that comes with knowing your products are free from potential hazards.

| Warranty: | 1 years | Sensitivity: | Highest | |

| Type: | Heightened custom metal detector | Alarm mode: | Buzzer Alarm,Support customization | |

| Customized support: | OEM, ODM | Detection type: | Magnetic Metal Detection | |

| Place of Origin: | Shanghai, China | Certification: | CE/ROHS/ISO9001 | |

| Brand Name: | Leimeng | Alarm method: | Belt Stop. Option: Alarm Lamp | |

| Model Number: | JGJC-1009 | Material: | 304 Stainless Steel | |

| Product name: | Heightened custom metal detector | Color: | Blue | |

| Application: | Food Metal Detector Needle Metal Detector | Best for: | Advanced | |

| Packaging Details | Conveyor metal detector in standard ply wooden case packing | Supply Ability | 100 Piece/Pieces per Month |

Lead time:

| Quantity(pieces) | 1 - 1 | 2 - 5 | 6 - 100 | >100 |

| Lead time (days) | 3 | 7 | 20 | To be negotiated |

| Detection principle | Double loop electromagnetic wave detection |

| Display method | Support customization |

| Detection height | 7-50 cm (support customization) |

| Alarm method | Sound and light alarm and conveyor belt stop, sound and light alarm and conveyor belt rewind and sound and light alarm conveyor belt forward |

| power | 150W |

| Detection width | 40-80 cm (support customization) |

| Sensitivity | 0-9 level adjustable |

| belt speed | 5-40m/min, the conveying speed can be adjusted |

| Detection sensitivity | Diameter 0.8-3.0mm iron ball, 1.5-5.0mm stainless steel |

| power supply | 100V-200V 50HZ |

| net weight | 200kg |

| volume | 165*100*95cm(length*width*height)(can be customized) |

| memory function | Can memorize 1-99 substances |

| Statistical methods | Total number of products, statistics of unqualified products, statistics of qualified products |

| metal identification | Identify iron, stainless steel and non-ferrous metals |

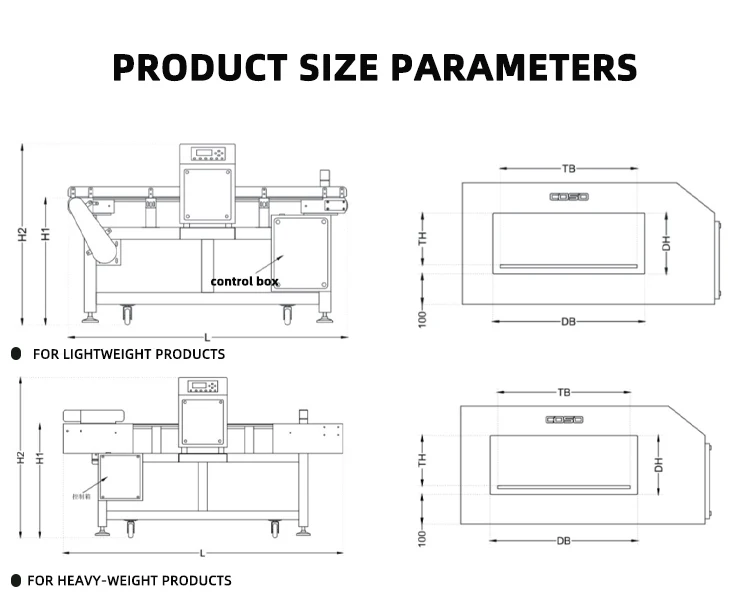

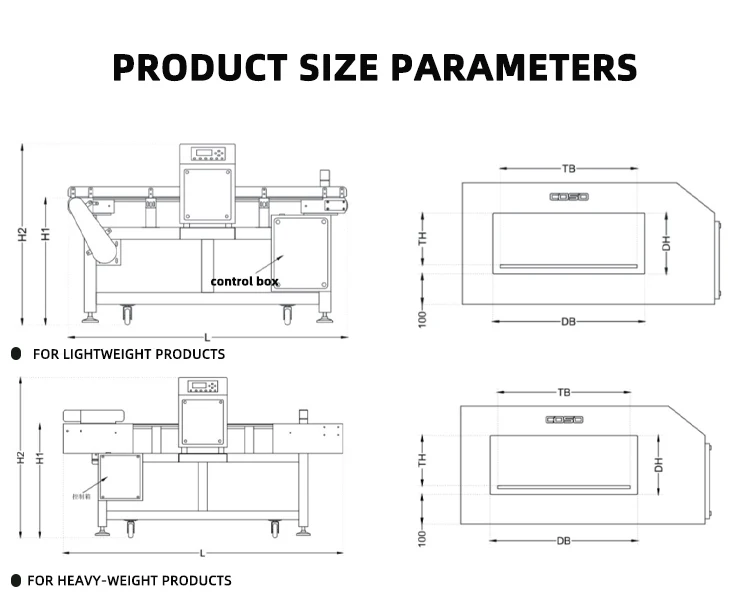

| Model | Size of whole machine(mm) | Size of detector(mm) | Sensitivity(mm) | ||||||

| H1 | H2 | L | W | DB | TB | DH | TH | FE/SUS | |

| 4010 | 700 | 900 | 1400 | 750 | 400 | 370 | 100 | 70 | 1.0/2.0 |

| 4012 | 700 | 920 | 1400 | 750 | 400 | 370 | 120 | 90 | 1.0/2.0 |

| 4015 | 700 | 950 | 1400 | 750 | 400 | 370 | 150 | 120 | 1.2/2.0 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 470 | 100 | 70 | 1.0/2.0 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 470 | 120 | 90 | 1.0/2.0 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 470 | 150 | 120 | 1.2/2.5 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 470 | 200 | 170 | 1.5/2.5 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 470 | 250 | 220 | 1.5/2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 470 | 300 | 270 | 2.0/3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 570 | 300 | 270 | 2.5/3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 570 | 350 | 320 | 3.0/4.0 |

| 6040 | 400 | 900 | 2000 | 950 | 600 | 570 | 400 | 370 | 3.5/4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 570 | 500 | 470 | 4.0/5.5 |

Introducing the High Sensitivity Automatic Fabric Clothes Scanner Metal Broken Needle Detector, a cutting-edge product designed to enhance the safety and efficiency of your garment production process. This state-of-the-art device is equipped with advanced technology that can detect even the tiniest metal fragments, ensuring that your garments are free from any potential hazards.

With its high sensitivity capabilities, the detector can quickly and accurately identify any broken needles or other metal debris that may have inadvertently found their way into your fabrics. This not only helps to prevent injuries to your workers but also ensures that your products meet the highest quality standards.

The automatic functionality of this detector allows for seamless integration into your production line, reducing the need for manual inspections and increasing productivity. The device is also incredibly easy to use, with a user-friendly interface that requires minimal training.

Investing in the High Sensitivity Automatic Fabric Clothes Scanner Metal Broken Needle Detector is a smart choice for any garment manufacturer looking to improve safety and quality control. Order yours today and experience the peace of mind that comes with knowing your products are free from potential hazards.

| Warranty: | 1 years | Sensitivity: | Highest | |

| Type: | Heightened custom metal detector | Alarm mode: | Buzzer Alarm,Support customization | |

| Customized support: | OEM, ODM | Detection type: | Magnetic Metal Detection | |

| Place of Origin: | Shanghai, China | Certification: | CE/ROHS/ISO9001 | |

| Brand Name: | Leimeng | Alarm method: | Belt Stop. Option: Alarm Lamp | |

| Model Number: | JGJC-1009 | Material: | 304 Stainless Steel | |

| Product name: | Heightened custom metal detector | Color: | Blue | |

| Application: | Food Metal Detector Needle Metal Detector | Best for: | Advanced | |

| Packaging Details | Conveyor metal detector in standard ply wooden case packing | Supply Ability | 100 Piece/Pieces per Month |

Lead time:

| Quantity(pieces) | 1 - 1 | 2 - 5 | 6 - 100 | >100 |

| Lead time (days) | 3 | 7 | 20 | To be negotiated |

| Detection principle | Double loop electromagnetic wave detection |

| Display method | Support customization |

| Detection height | 7-50 cm (support customization) |

| Alarm method | Sound and light alarm and conveyor belt stop, sound and light alarm and conveyor belt rewind and sound and light alarm conveyor belt forward |

| power | 150W |

| Detection width | 40-80 cm (support customization) |

| Sensitivity | 0-9 level adjustable |

| belt speed | 5-40m/min, the conveying speed can be adjusted |

| Detection sensitivity | Diameter 0.8-3.0mm iron ball, 1.5-5.0mm stainless steel |

| power supply | 100V-200V 50HZ |

| net weight | 200kg |

| volume | 165*100*95cm(length*width*height)(can be customized) |

| memory function | Can memorize 1-99 substances |

| Statistical methods | Total number of products, statistics of unqualified products, statistics of qualified products |

| metal identification | Identify iron, stainless steel and non-ferrous metals |

| Model | Size of whole machine(mm) | Size of detector(mm) | Sensitivity(mm) | ||||||

| H1 | H2 | L | W | DB | TB | DH | TH | FE/SUS | |

| 4010 | 700 | 900 | 1400 | 750 | 400 | 370 | 100 | 70 | 1.0/2.0 |

| 4012 | 700 | 920 | 1400 | 750 | 400 | 370 | 120 | 90 | 1.0/2.0 |

| 4015 | 700 | 950 | 1400 | 750 | 400 | 370 | 150 | 120 | 1.2/2.0 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 470 | 100 | 70 | 1.0/2.0 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 470 | 120 | 90 | 1.0/2.0 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 470 | 150 | 120 | 1.2/2.5 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 470 | 200 | 170 | 1.5/2.5 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 470 | 250 | 220 | 1.5/2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 470 | 300 | 270 | 2.0/3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 570 | 300 | 270 | 2.5/3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 570 | 350 | 320 | 3.0/4.0 |

| 6040 | 400 | 900 | 2000 | 950 | 600 | 570 | 400 | 370 | 3.5/4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 570 | 500 | 470 | 4.0/5.5 |

content is empty!