| Availability: | |

|---|---|

| Quantity: | |

Leimeng

The advantages of large weight weighing equipment include:

1. High precision: Large weight weighing equipment usually has high-precision weighing capacity, which can accurately measure the weight of heavy objects and meet various accuracy requirements.

2. High load-bearing capacity: These devices are designed for weighing heavy objects and have high load-bearing capacity, which can safely carry and measure large weight objects.

3. Durable and reliable: Large weight weighing equipment usually uses sturdy and durable materials and structures to cope with the long-term use of heavy objects and the requirements of various working environments, with high reliability and durability.

4. Multifunctionality: Some large weight weighing equipment is also equipped with various functions, such as data recording, remote monitoring, alarm, etc., providing more convenience and flexibility.

5. Safety: These devices usually have safety protection measures, such as anti slip design, overload protection, protective covers, etc., to ensure the safety of operators and equipment.

6. Improving efficiency: Large weight weighing equipment can quickly and accurately complete weighing tasks, improve work efficiency, and save labor and time costs.

7. Widely used: These devices are widely used in logistics, warehousing, production and other fields, suitable for weighing various types of heavy objects and meeting the needs of different industries.

The following are common questions and answers about weighing equipment:

Q: What is a weighing device?

A: Weighing equipment is a technology and equipment used to measure the weight of objects. It includes various types of scales, weighing sensors, and weighing systems.

Q: What is the working principle of weighing equipment?

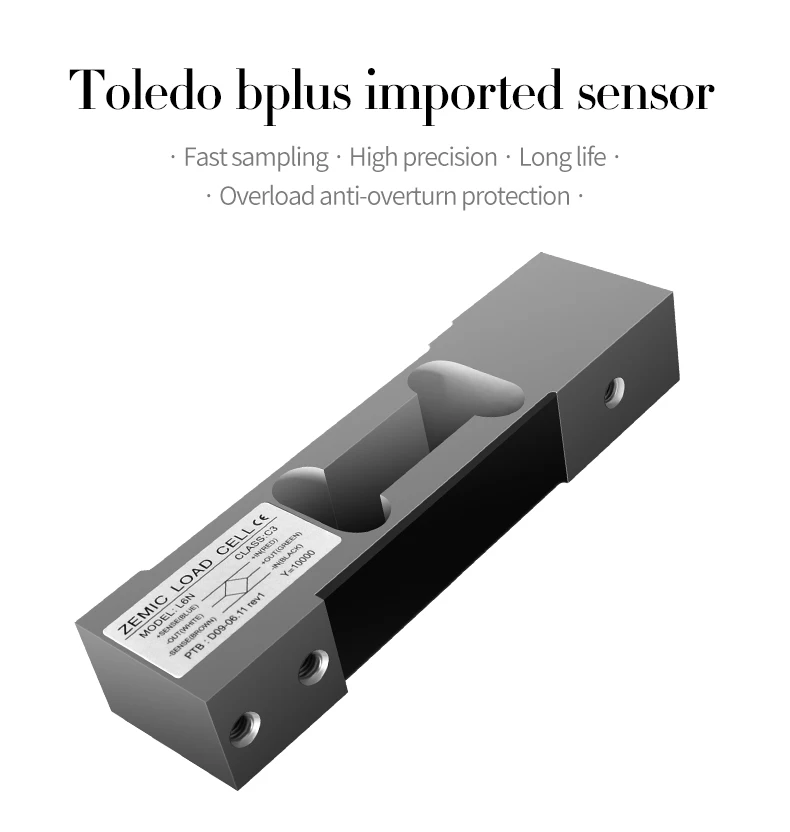

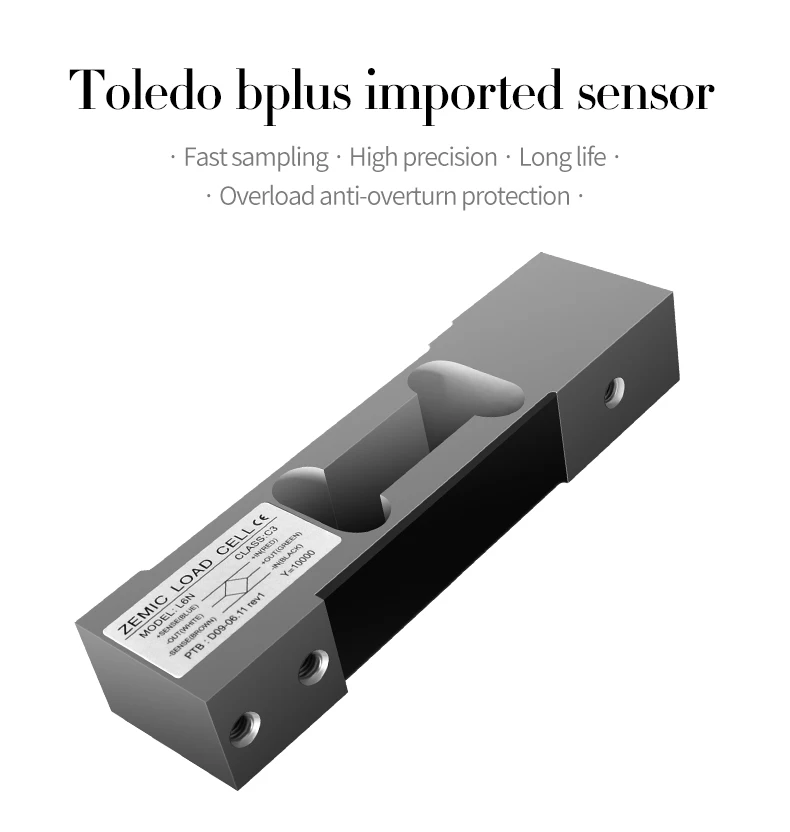

A: The working principle of weighing equipment is based on force measurement. It uses pressure sensors, load cells, or other weighing sensors to detect the force exerted by an object and convert it into the corresponding weight value.

Q: What are the application areas of weighing equipment?

A: Weighing equipment is widely used in fields such as logistics, manufacturing, healthcare, retail, and agriculture. They are used for cargo weighing, production process control, medical monitoring, food distribution, and retail transactions.

Q: How accurate is the weighing equipment?

A: The accuracy of weighing equipment varies depending on the type of equipment and application. Generally speaking, the accuracy of commercial scales is usually between 0.1% -0.01%, while the accuracy of high-precision laboratory scales can reach 0.001% or higher.

Q: How to calibrate the weighing equipment?

A: The method of calibrating weighing equipment varies depending on the equipment. Typically, the calibration process involves comparing known weights, adjusting device settings, or adjusting the sensitivity of load cells to ensure accurate weight measurement.

Q: What are the maintenance requirements for weighing equipment?

A: The maintenance of weighing equipment includes regular cleaning of equipment, inspection and replacement of damaged components, calibration of equipment, and maintaining a suitable environment. The specific maintenance requirements should be based on the recommendations of the equipment manufacturer.

Q: Can the weighing equipment be connected to other systems?

A: Yes, some weighing equipment can be connected to other systems such as computers, control systems, or data management systems to achieve functions such as data recording, remote monitoring, and automation control.

Q: Can weighing equipment measure multiple objects?

A: Yes, weighing equipment can measure the weight of a single object or the cumulative weight of multiple objects, depending on the design and functionality of the equipment.

The advantages of large weight weighing equipment include:

1. High precision: Large weight weighing equipment usually has high-precision weighing capacity, which can accurately measure the weight of heavy objects and meet various accuracy requirements.

2. High load-bearing capacity: These devices are designed for weighing heavy objects and have high load-bearing capacity, which can safely carry and measure large weight objects.

3. Durable and reliable: Large weight weighing equipment usually uses sturdy and durable materials and structures to cope with the long-term use of heavy objects and the requirements of various working environments, with high reliability and durability.

4. Multifunctionality: Some large weight weighing equipment is also equipped with various functions, such as data recording, remote monitoring, alarm, etc., providing more convenience and flexibility.

5. Safety: These devices usually have safety protection measures, such as anti slip design, overload protection, protective covers, etc., to ensure the safety of operators and equipment.

6. Improving efficiency: Large weight weighing equipment can quickly and accurately complete weighing tasks, improve work efficiency, and save labor and time costs.

7. Widely used: These devices are widely used in logistics, warehousing, production and other fields, suitable for weighing various types of heavy objects and meeting the needs of different industries.

The following are common questions and answers about weighing equipment:

Q: What is a weighing device?

A: Weighing equipment is a technology and equipment used to measure the weight of objects. It includes various types of scales, weighing sensors, and weighing systems.

Q: What is the working principle of weighing equipment?

A: The working principle of weighing equipment is based on force measurement. It uses pressure sensors, load cells, or other weighing sensors to detect the force exerted by an object and convert it into the corresponding weight value.

Q: What are the application areas of weighing equipment?

A: Weighing equipment is widely used in fields such as logistics, manufacturing, healthcare, retail, and agriculture. They are used for cargo weighing, production process control, medical monitoring, food distribution, and retail transactions.

Q: How accurate is the weighing equipment?

A: The accuracy of weighing equipment varies depending on the type of equipment and application. Generally speaking, the accuracy of commercial scales is usually between 0.1% -0.01%, while the accuracy of high-precision laboratory scales can reach 0.001% or higher.

Q: How to calibrate the weighing equipment?

A: The method of calibrating weighing equipment varies depending on the equipment. Typically, the calibration process involves comparing known weights, adjusting device settings, or adjusting the sensitivity of load cells to ensure accurate weight measurement.

Q: What are the maintenance requirements for weighing equipment?

A: The maintenance of weighing equipment includes regular cleaning of equipment, inspection and replacement of damaged components, calibration of equipment, and maintaining a suitable environment. The specific maintenance requirements should be based on the recommendations of the equipment manufacturer.

Q: Can the weighing equipment be connected to other systems?

A: Yes, some weighing equipment can be connected to other systems such as computers, control systems, or data management systems to achieve functions such as data recording, remote monitoring, and automation control.

Q: Can weighing equipment measure multiple objects?

A: Yes, weighing equipment can measure the weight of a single object or the cumulative weight of multiple objects, depending on the design and functionality of the equipment.

content is empty!